Downdraft Table New Downdraft Grinding Big Size

$1100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

$1100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

Model No.: 1500

Brand: jy

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Service System: Online Support

Type: Fabric Dust Collector

Dust Collecting Method: Dry

Medium Material: Chemical Synthetic Fiber

| Selling Units | : | Set/Sets |

| Package Type | : | Seaworthy packing |

Industrial portable grinding operation platform downdraft table

1. The dust enters the purification and dust removal workbench under the suction of the centrifugal fan. Large particles of dust enter the dust collection drawer by gravity settlement. The remaining small particles of dust pass through the filter cartridge of the purification dust removal workbench and are blocked in the filter element. On the outer wall, the clean gas is discharged into the surrounding air by the fan, so that the dust-containing gas can be effectively purified.

2. After prolonged use, more and more dust is attached to the outer surface of the filter cartridge, and the resistance increases, resulting in a significant decrease in air volume. At this time, the pulse dust cleaning device is started to back-clean the filter cartridge and use the compressed air. Power, the dust on the outer wall of the filter cartridge is shaken down and collected in the dust collection drawer, so as to ensure the smooth use of the filter cartridge for a long time and achieve a stable dust collection effect.

More products, Baghouse Dust Collector, Cyclone Dust Collector, Welding Fume Extractor, Fog Cannon, Bulk Material Handling Equipment, Screw Flight

Product Description

Polishing and dust removing workbench:

It is a light and effective grinding and dusting table equipment specially designed for various welding, polishing, grinding and deburring of workpieces, plasma cutting when welding operations in mechanical processing plants, automobile assembly plants, repair plants and related industries.

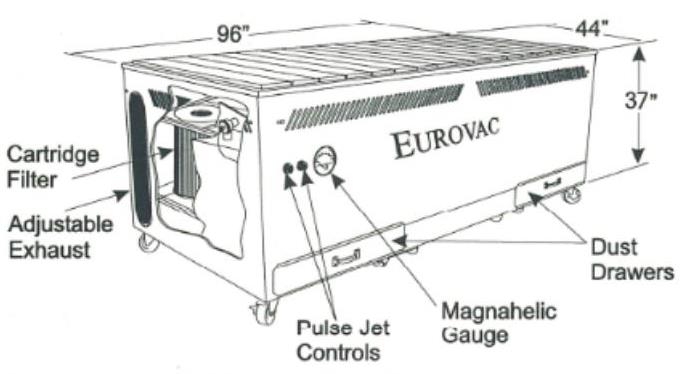

The powerful 5 H.P. motor and fan generates 4000 C.F.M. drawing dust through the table top and side slots; around the outside of the plenum and through the sides of the filters. The filters cause the dust to fall into the drawers below. The clean air inside the filters is drawn through the plenum and exhausted through the adjustable flow direction damper.

Self contained motor and fan provide more work space. There is sufficient air movement for two technicians to work side by side or at each end of the table. The table can be easily moved to another work area.

The polyester cartridge filters won't clog up like Bag Filters and are easily cleaned by compressed air pulse jet cleaning.

Product Structure

Exquisite workmanship, ingenuity quality

Product Specifications

Let you better choose the right product

Specification Motor Filter cartridge Air volume Filter area Cleaning method

800*1100*1600 2.2kw 325*500 3000m³/h 9m2/h Automatic pulse cleaning

1200*1200*1600 2.2kw 325*500 3000m³/h 18m2/h Automatic pulse cleaning

1500*1200*1600 3.0kw 325*500 4000m³/h 18m2/h Automatic pulse cleaning

2000*1000*1600 2.2kw 325*500 4500m³/h 18m2/h Automatic pulse cleaning

2000*1200*1600 2.2kw 325*500 7000-8500m³/h 40m2/h Automatic pulse cleaning

Advantages

Application

FAQ

1.How about your machine quality?

We have own research and development team,rich experiences technicians,and professional workers. We pay attention to every detail in manufacturing to ensure machines with high quality.

2.What is the status of After-sale Services for customers and machineries?

We provide the technical support for the whole life for free. Also, Engineers available to service machinery overseas. But the customers/buyer should pay for engineer salary 100$/day.

3. How to visit our company?

1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi(1hour),then we can pick up you.

2.Fly to Shanghai Airport:By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3.Fly to Guangzhou aiport:By air From Guangzhou to Beijing airpot:By high speed train From Beijing Nan to Cangzhou Xi(1 hour), then we can pick up you.

4.How many years since you have been in this field?

Our company has been in this field for almost 20years. We have rich experience for manufacturing and designing the machines.

5.How can I contact you ?

Please look at my contact card. You can talk to me anytime.Or send me enquiry email, I will reply you in 24 hours and offer the optimum solution to you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.